Sheetfed Printing 101.

Sheetfed printing process, and capabilities found here!

Sheet-Fed Printing Made Simple:

Sheet-fed printing, also known as offset printing, is a widely used method for creating high-quality prints. Unlike web printing, which uses continuous rolls of paper, sheet-fed printing involves individual sheets of paper being fed into the press for printing.

How Sheet-Fed Printing Works:

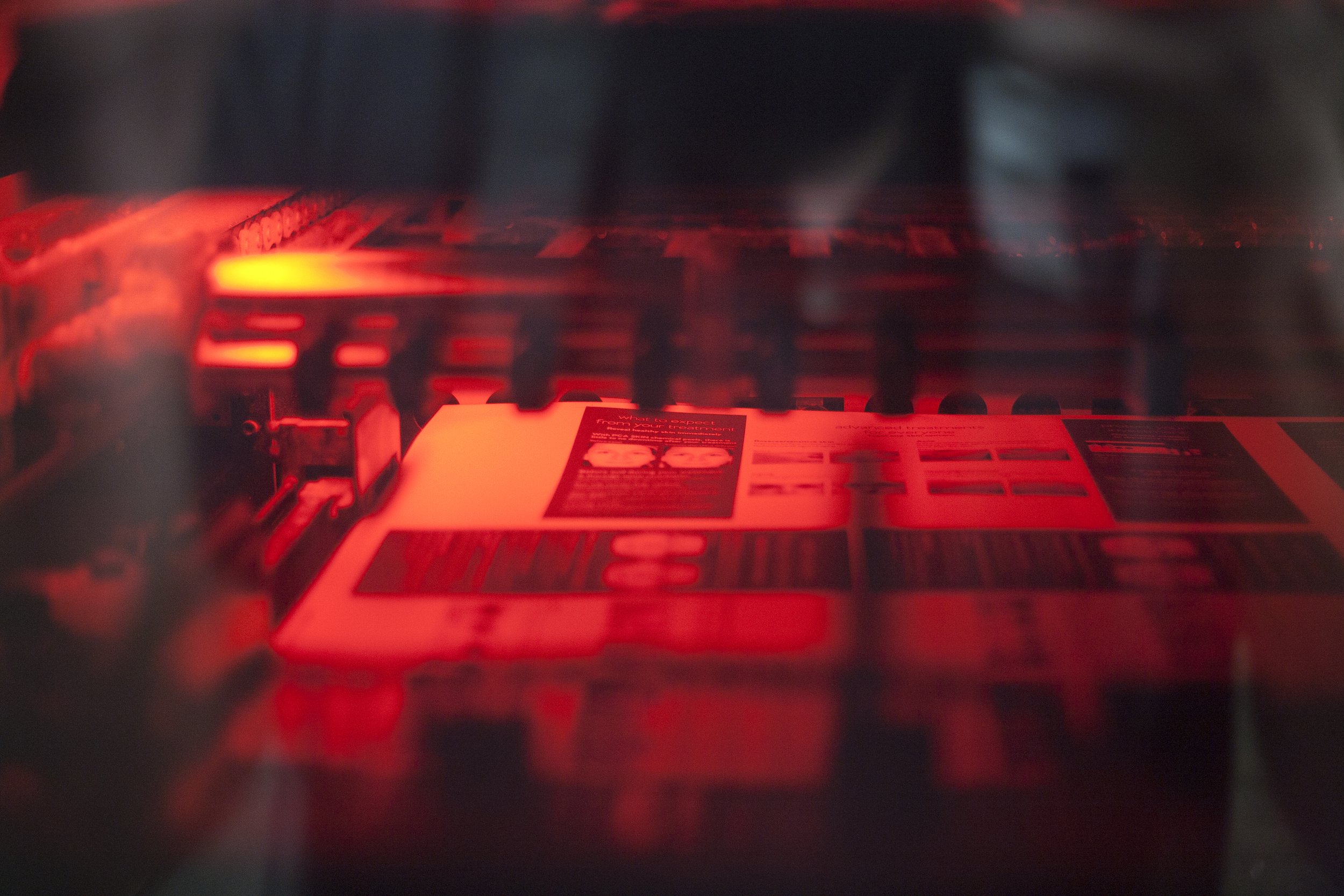

Feeding Paper: Sheets of paper are fed into the press one at a time.

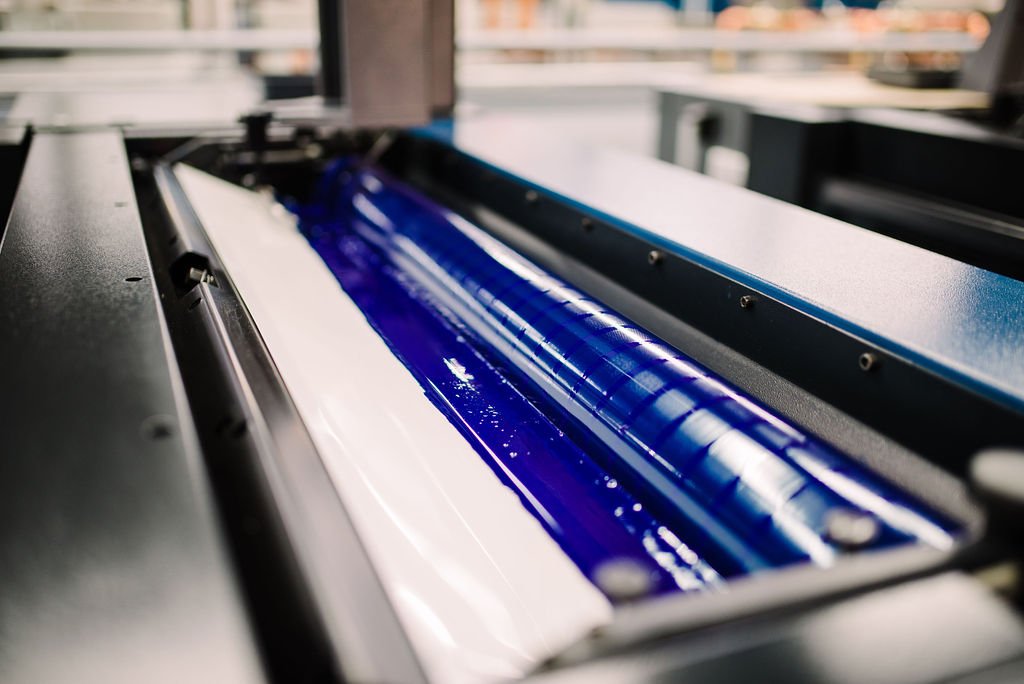

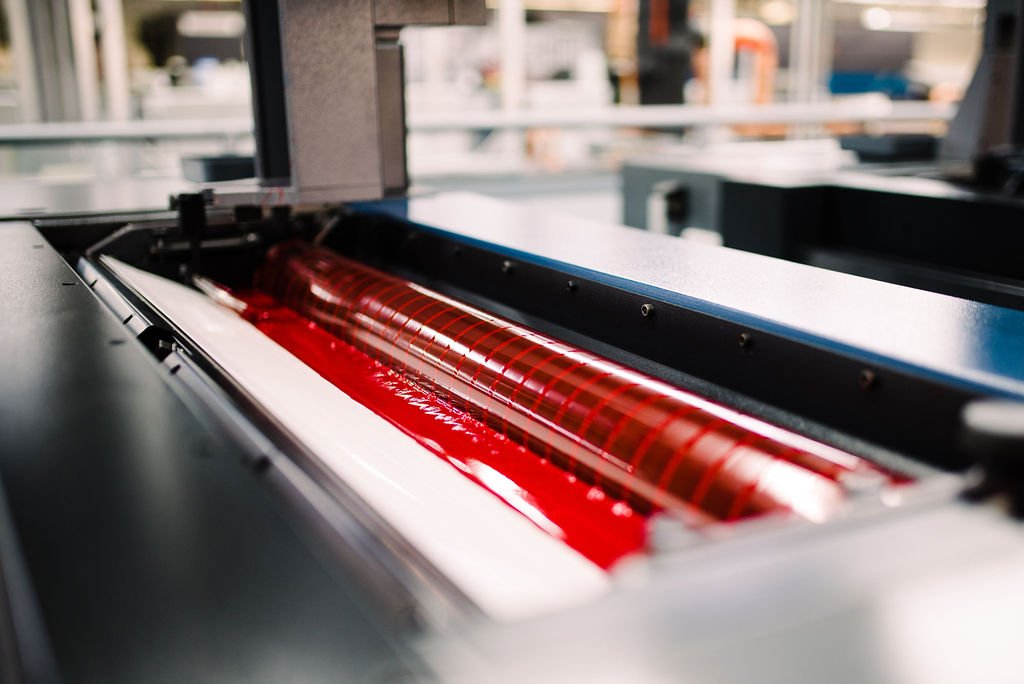

Ink Application: Ink is applied to the paper using a printing plate and a rubber blanket.

Drying: The ink is dried quickly to prevent smudging.

Finishing: The printed sheets are stacked and ready for further processing.

Advantages of Sheet-Fed Printing:

High Quality: Produces sharp, detailed prints.

Versatility: Can print on various paper sizes and thicknesses.

Quick Setup: Ideal for short print runs and on-demand printing.

Color Control: Ensures consistent and accurate colors.

Applications of Sheet-Fed Printing:

Marketing Materials: Brochures, flyers, posters.

Packaging: Boxes, cartons, labels.

Publishing: Books, magazines, publications.

Why It's Called Offset Printing:

Offset printing refers to the indirect transfer of ink from the printing plate to the paper. The image is first transferred to a rubber blanket before being applied to the paper. This process creates a clean, crisp image.

In summary, sheet-fed printing, or offset printing, is a versatile and high-quality printing method suitable for a wide range of printing needs. Whether you're printing marketing materials, packaging, or publications, sheet-fed printing delivers professional results.

3 Benefits of Sheetfed Printing.

Automated Process

Sheet-fed printing is more automated than it sounds. The machine automatically feeds sheets, offering flexibility in product size. Small feet within the machine pick up the paper and feed it through the press, while rollers keep it moving until grip pieces secure it. This efficiency reduces costs and allows for more flexibility in paper sizes up to 28x 41 inches.

Specialty Finishes

Sheet-fed printing offers specialty finishes like gloss, matte, and dull, adding flair to your finished products. Choose from aqueous soft-touch materials for an even smoother finish or opt for UV finishes, including spot or overall gloss, dull, textured, matte, and glitter options. With sheet-fed presses, achieving unique finishes for your project is a breeze!

Faster Printing

All sheet-fed printing is very quick, making it easy to print large quantities. This efficiency lowers costs, which is helpful when printing high volume. Sheet-fed printing machines can also handle all types of products, from small postcards to full-size calendars, catalogs and everything in between.